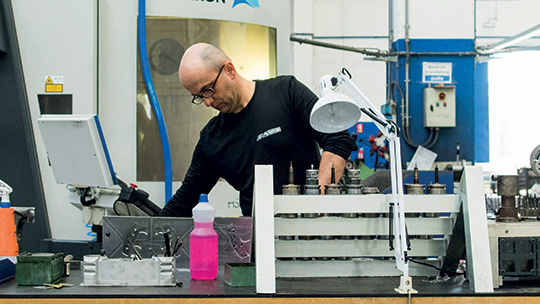

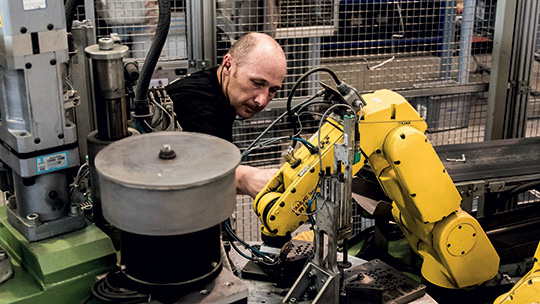

L.M. Monticelli is the only company that specialises exclusively in corner joints, from their design and development to the manufacture of the finished piece.

The manufacturing process is carried out solely in Italian factories, with all our resources dedicated to this process. Attention to detail is translated into top quality brackets. All the resources at our disposal are dedicated to our quality control system, which has the ultimate goal of providing complete customer satisfaction.

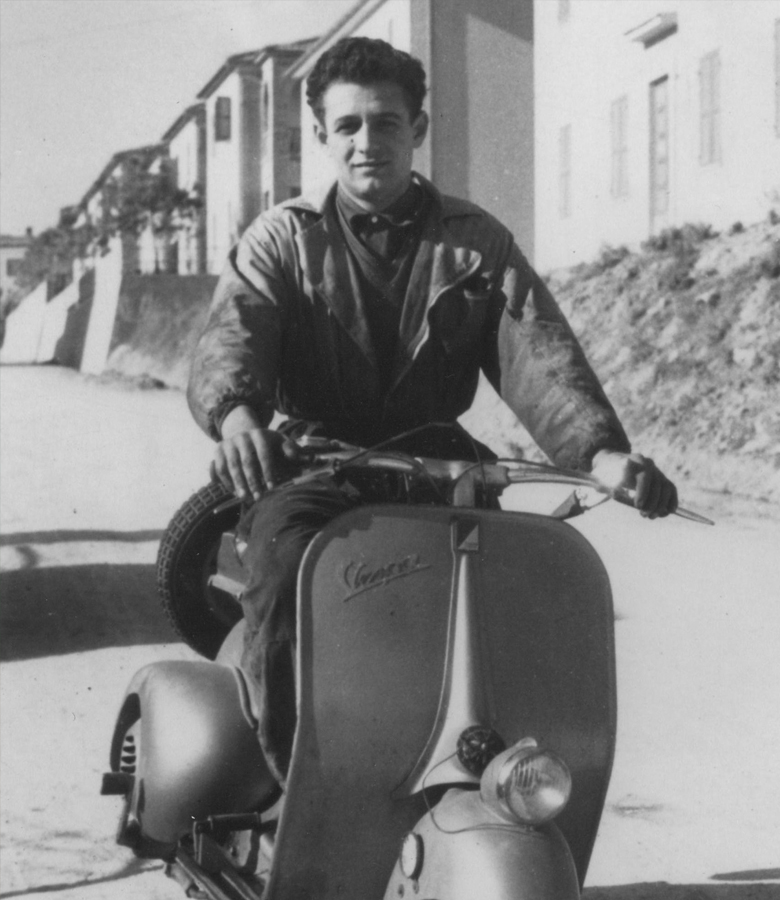

The founder

Domenico Monticelli

Born in Osimo on 8th December 1933, he started working at the age of 5, at 22 he became father and moved to France in search of a job with his wife Giuseppina and their young daughter Sonia.

He made his return to Italy in 1969 with his four children with a lot of determination and will power.

An old-fashioned man of humble origins, Domenico was very determined, generous, honest and devoted to work and his family which he loved unconditionally.

Every promise was a debt for him. The given word was worth more than a hundred contracts. In his everyday home and work life, Domenico created L.M. dei F.lli Monticelli, the “workshop” as he liked to call it, with his children. The company has had a significant importance for the territory by creating work places for many families. Far sighted and with discretion, he was active in social fields. Tenacious, determined and with an iron will, he lived like a lion to the very end leaving behind a reality embedded in the territory of the Marche region.

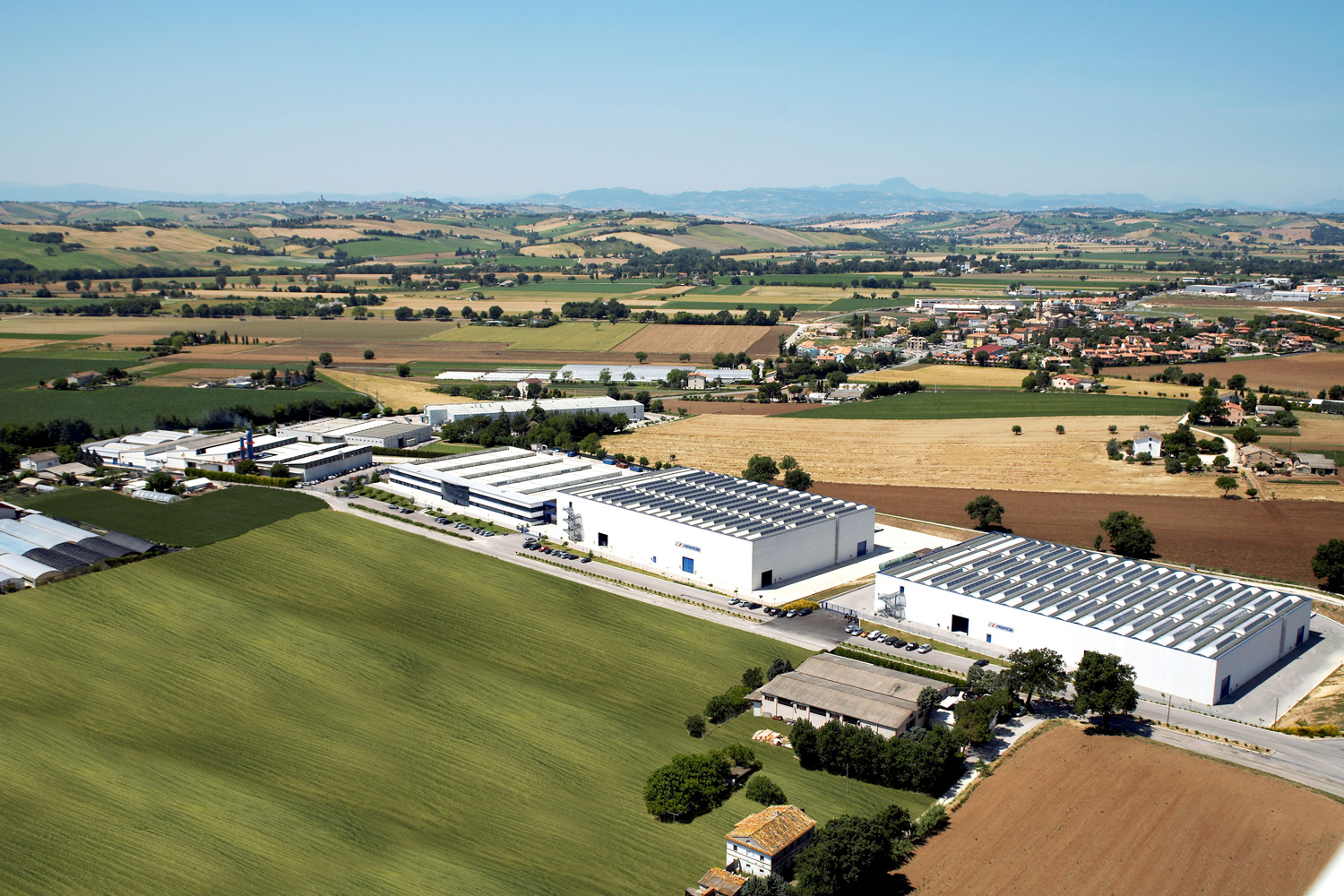

25.000sm

PLANTS

80+

COUNTRIES IN THE WORLD

220+

COLLABORATORS

850+

CLIENTS

SAFETY AND EDUCATION

L.M. MONTICELLI has always made available its means and financial and human resources to achieve the goal of improving Workers’ Safety and Health, as an integral part of its business and as a strategic commitment to achieve the general goals of its corporate activity.

We implement methods, interventions and improvements to reduce accidents, occupational diseases and related indices. We ensure the proper application of the technologies we use and, where possible, pursue the improvement or adoption of more advanced technologies from a health and safety perspective. We identify hazards arising from various activities, assess their risks and take appropriate prevention and protection measures.

Moreover, we promote education, information, and training activities for all our employees and we make them aware of their individual obligations and the importance of their individual actions in achieving the expected results. Engagement, participation and dissemination of awareness is an integral part of our corporate policy and objectives to promote a prevention-oriented culture and ensure continuous safe working conditions. Finally, also regarding our suppliers and contractors, our selection takes place according to the principles of this policy, requiring them to commit to maintain a conduct that is consistent with it.

DOWNLOAD

ENVIRONMENT VALUE

Effective from the beginning of 2014, the Top Management of the Company chose to implement an environmental management system to control and reduce the impact of its activities on the surrounding environment. For this reason, L.M. Monticelli decided to implement an ENVIRONMENTAL MANAGEMENT SYSTEM that complies with the requirements of the UNI EN ISO 14001:2015 standards.

We believe in eco-sustainable growth, so we implemented the principles of environmental management in our product development and production processes. We constantly improve the impact of our business on the environment, through careful waste management. Our staff is trained and updated periodically to improve waste separate collection and disposal; low-consumption lighting, with LED lights everywhere, both inside departments and in outdoor yards and careful management of chemicals, choosing the safest products both for people and the environment.

In the last few years, we have also committed ourselves to many technical interventions for energy efficiency, including the installation of a photovoltaic system that produces 212 Kw/p (a project co-financed by the European Regional Development Fund), after a careful study of the energy consumption by time bands, so as to use solely self-generated energy; the development of hot air recovery systems from the foundry to preheat the aluminum and thus reduce energy consumption; the installation of inverters on all old machinery to save energy and the installation of an extensive network of meters to monitor every machinery in every sector.

Continuous Emission Monitoring System (CEMS)

The Continuous Emissions Monitoring System (CEMS) is able to verify emission levels in the atmosphere of hourly and daily average concentration of particulate matter (mg/Nm3) by continuously acquiring data in the field, without any supervision and under all environmental conditions. Particulate matter is generated during the melting process of the aluminum alloys, that takes place inside the melting furnaces of the holding furnaces in the foundry department.

DOWNLOAD

In 2015, the company obtained the first environmental certification of the environmental management system (EMS), according to UNI-EN-ISO 14001:2004, with the issuing of Certificate No. EMS-5821/S of 04/13/2015. We subsequently recertified our EMS according to the new UNI-EN-ISO 14001:2015, with the issue of Certificate No. EMS-5821/S dated 12/04/2021 by the notified body RINA SERVICE. Every year an audit is carried out for maintenance by the certifying body and every 3 years the renewal is carried out, the last one in 2021, with a new issue of Certificate No. EMS-5821/S dated 12/04/2021, which it will therefore expire in 2024.

We believe in eco-sustainable growth, which is why we have implemented environmental management principles in the development of our products and production processes. We continuously improve the impact of our activity on the environment through careful waste management - staff are trained and updated periodically to improve waste differentiation and disposal; low consumption lighting, with LED lights everywhere, both inside the departments and in the external squares; careful management of chemical substances, choosing the safest products for humans and the environment.

In recent years we have also engaged in numerous technical interventions for energy efficiency, including the installation of a photovoltaic system which develops for 212 Kw/p (Project co-financed by the European Regional Development Fund), with a study awaiting energy consumption by time slots, in order to use all self-produced energy; the development of systems for recovering hot air from the foundry, to preheat the aluminum and therefore reduce energy consumption; the application of inverters on all old machinery to save energy; the installation of a large network of meters to keep every machine in every sector under control.